Thanks to partner company Elettromeccanica Piossasco’s long experience our range of threephase oil-immersed transformers is able to satisfy even the most demanding customer requests in terms of:

-

Energy efficiency and consumption reduction;

-

Low noise;

-

Possibility of installation in tropical countries with temperatures up to +55°C;

-

Customized manufacture upon customers’ technical requirements;

-

Technical and sales assistance in project development.

Standard manufacture

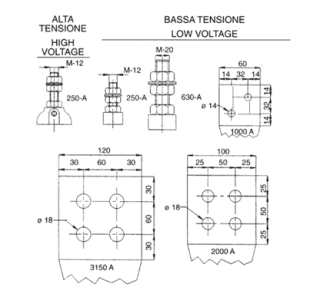

- 1 – HV porcelain bushings;

- 2 – LV porcelain bushings and neutral;

- 3 – tap changer operated from the outside with transformer disconnected;

- 4 – thermometer pocket;

- 5 – lifting lugs;

- 6 – oil conservator (from 630 to 3150 kVA);

- 7 – level display (for transformers with oil conservator);

- 8 – silicalgel capsule (for transformers with conservator);

- 9 – filling hole, type 1: bursting valve for transformers with conservator, type2: overpressure valve for ermetically sealed transformers;

- 10 – bi-directional rollers;

- 11 – emptying valve;

- 12 – earthing terminal;

- 13 – data plate.

Customization upon request

- 14 – thermometer with two N.O. contacts alarm trip;

- 15 – relé bucholz with two N.O. contacts alarm trip (for transformers with oil conservator);

- 16 – DGPT2 device (for hermetically sealed transformers, without oil conservator) or, as an alternative, RIS device;

- electronic TPL210 device, with NT210 monitoring unit of temperature, pressure and oil level for hermetically sealed transformers;

- over pressure valve with electric contact;

- primary voltage up to 36kV;

- double primary voltage;

- double or multiple secondary voltage for use in photovoltaic systems;

- non-standard losses and voltages;

- non standard connections and vector groups;

- Hz 60 frequency;

- MV elastimold type connectors;

- passe-barre type LV connectors;

- MV/LV air cable boxes;

- MV connector protections;

- pole-mounting slids;

- auxillary junction box;

- silicon or vegetable oil;

- electrostatic shield between primary and secondary windings;

- metal OR PVC oil retention bund;